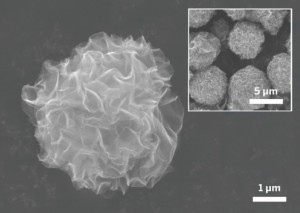

The 5-µm-diameter graphene balls in these scanning electron microscope images contain graphene nanosheets radiating outward from the center.

Credit: Chem. Mater.

Materials scientists have developed a new technique that could provide a simpler and more effective way to produce electrode materials for batteries and supercapacitors, which could potentially lead to devices with improved energy and power densities.

The researchers have unlocked this new battery technology by exposing tiny bits of graphene to a process that is very similar to deep-frying.

Prior to this development, scientists had difficulty using graphene in electrodes due to the difficulty encountered when processing the material. However, the researchers out of Yonsei University have learned how to harness the material’s electrical and mechanical properties while retaining its high surface are by using an alternative technique.

This from Chemical & Engineering News:

The researchers simply passed an aqueous suspension of graphene oxide flakes through an ultrasonic nozzle, which uses sound waves to break the suspension into microdroplets. They sprayed the droplets downward into a 160 °C mixture of an organic solvent and ascorbic acid, a reducing agent.

“This rapid evaporation of water, we believe, is responsible for the radially outward arrangement of the graphene nanosheets,” says Sang-Hoon Parker, a materials scientist at Yonsei University.

For more information on the future of battery technology, make sure to attend the ECS Conference on Electrochemical Energy Conversion & Storage with SOFC-XIV. This is the first of a series of planned biennial conferences in Europe by ECS on electrochemical energy conversion/storage materials, concepts, and systems, with the intent to bring together scientists and engineers to discuss both fundamental advances and engineering innovations.

In the meantime, make sure to check out the latest research in our Digital Library on battery technology!