According to the Federal Aviation Administration, nearly 7,000 laser strikes on aircrafts were reported in 2017.

“In cities like Chicago this problem is real as people are shining laser pointers on aircrafts during critical phases of flight, which is a big nuisance to pilots,” said Jason Keleher, a professor and chair of chemistry at Lewis University, who was approached by the aviation department at Lewis University to collaborate on a solution to this growing problem .

“Is it a bunch of kids? Is it accidental? Is somebody just like, ‘I bet you can’t hit that plane with those lasers.’ It’s really hard to identify who’s actually doing it. It’s a very interesting problem,” said Keleher, one he, the project’s principal investigator, was prepared to solve.

Keleher explains that although the lasers don’t cause permanent eye damage to pilots as they maneuver the aircraft, it does cause temporary flash blindness which may make it difficult for pilots to see control systems as they prepare for take-off and landing. He explains it is similar to the way high beams can disorient a driver upon direct exposure.

“That’s what it looks like from looking out the cockpit windshield at the ground because the beam expands when it hits the windshield,” said Keleher, referring to the photo on the left.

To combat this issue, Keleher and his research partner Daniel Maurer, an undergraduate student at Lewis University, propose to integrate a nanocomposite liquid crystal containing layer into existing windshield designs. While other researchers have used pull-down windscreens or goggles to deal with lasers, the solutions prove inconvenient as they require the flight crew to take these precautions whether or not they are actually being targeted, according to an ACS Newsroom press release.

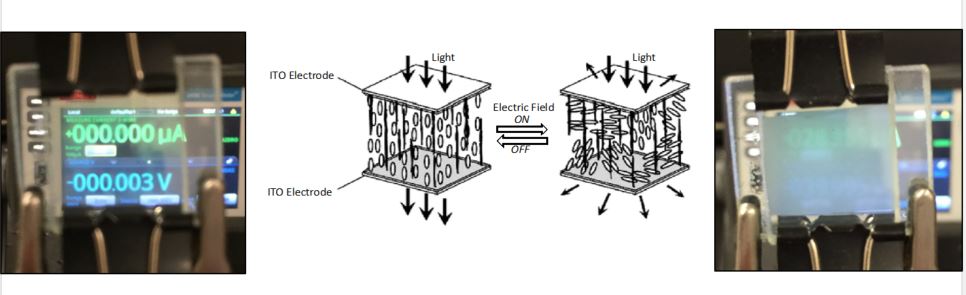

The team placed a solution of liquid crystals called N-(4-methoxybenzylidene)-4-butylaniline (MBBA) between two 1-inch-square panes of glass. MBBA has a transparent liquid phase and an opaque crystalline phase that scatters light. By applying a voltage to the apparatus, the researchers caused the crystals to align with the electrical field and undergo a phase change to the more solid crystalline state, consequently turning the glass to frost to block the laser’s light.

The photo depicts how the liquid crystals work to take the window from a transparent state to a frosted state in order to block light.

When the beam is removed, the system power is turned off, and the liquid crystals return to their transparent, liquid state.

(Read the full press release here.)

Areas of the windshield that have not been hit by the laser remain transparent at all times. This is done by segmenting the window and only targeting the sections needed by using small, built-in tiles of liquid crystals to make up the windshield as a whole.

“We’re still in the laboratory phases, but ever since our press conference at the ACS Spring 2019 National Meeting & Exposition, people have been calling like crazy to talk to us,” said Keleher of the positive response to the work.

For those interested in picking Keleher’s brain a bit more on the subject or hearing him speak live, he will be presenting his talk on “Unraveling Synergistic Interactions driving the Chemical Mechanical Planarization Process” on Tuesday, May 28 at 235th ECS Meeting in Dallas, TX. His paper, available now in the JSS Focus Issue on CMP for Sub-10 nm Technologies, is one of the most-read ECS Journal of Solid State Science and Technology (JSS) articles by TIA in Q1 2019—already garnering an Altmetric score of 22.

It will cover key interactions through a series of case studies focusing on probing the impact of inhibitor structure on the substrate surface energy relevant to Cu CMP, the role of slurry chemistry on controlling defectivity during STI post-CMP cleaning, and effect of organic additives on the modulation of nanoparticle surface properties to enhance STI CMP performance.

The DK Lab, made up of undergraduate and graduate students focusing on nanocomposite materials for various applications ranging from aviation, safety, health, and more.

In addition, eight of his students from the Keleher Research Group (DK Lab) will also present at the meeting.

“For the students, ECS meetings align with the things that we do. They get to interact, not only with other graduate students and undergrad students, but they get to interact with faculty from other universities, as well as companies and corporate entities,” said Keleher. “I can tell you right now, bringing students to ECS meetings is a huge networking experience for them. I mean, they make connections that not only lead to discussions there but potential interactions for them when they get out of school.” said Keleher.

As for Keleher, he says, “ECS has always been at the core of what I do because our research has a significant electrochemistry focus and most importantly it highlights one of our big areas, chemical mechanical planarization.”

Adding Keleher, “ECS is really our medium.”

For more information on the Keleher Research Lab follow them on Twitter at DKLab_LewisU.

Reach Keleher directly at keleheja@lewisu.edu.