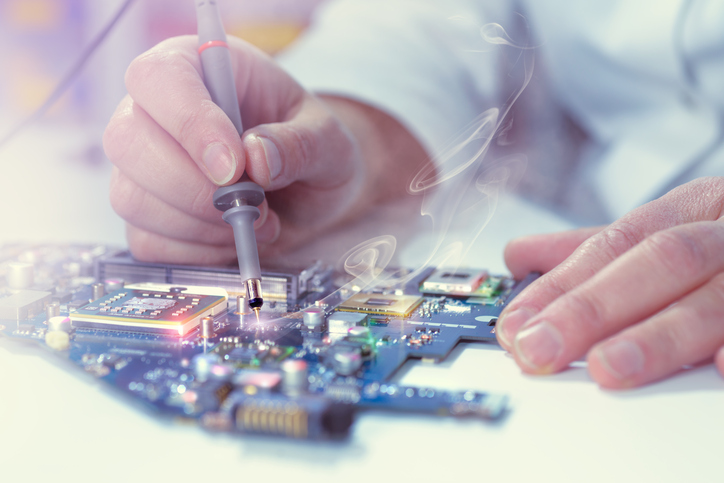

Researchers have developed an inexpensive and scalable technique that can change plastic’s molecular structure to help it cast off heat.

Researchers have developed an inexpensive and scalable technique that can change plastic’s molecular structure to help it cast off heat.

Advanced plastics could usher in lighter, cheaper, more energy-efficient product components, including those used in vehicles, LEDs, and computers—if only they were better at dissipating heat.

The concept can likely be adapted to a variety of other plastics. In preliminary tests, it made a polymer about as thermally conductive as glass—still far less so than metals or ceramics, but six times better at dissipating heat than the same polymer without the treatment.

“Plastics are replacing metals and ceramics in many places, but they’re such poor heat conductors that nobody even considers them for applications that require heat to be dissipated efficiently,” says Jinsang Kim, a materials science and engineering professor at the University of Michigan. “We’re working to change that by applying thermal engineering to plastics in a way that hasn’t been done before.”

Scientists have turned wood into an electrical conductor by making its surface graphene.

Scientists have turned wood into an electrical conductor by making its surface graphene. Scientists have found a way to make carbon both

Scientists have found a way to make carbon both  A team of researchers has created a new material that could be used in microscopic sensors, also known as microelectromechanical systems [MEMS], for devices that are part of the Internet of Things.

A team of researchers has created a new material that could be used in microscopic sensors, also known as microelectromechanical systems [MEMS], for devices that are part of the Internet of Things. A quantum probe based on an atomic-sized “color center” in diamonds has let researchers observe the flow of electric currents in graphene.

A quantum probe based on an atomic-sized “color center” in diamonds has let researchers observe the flow of electric currents in graphene. Two discoveries could provide a simple and effective way to “stencil” high-quality 2D materials in precise locations and overcome a barrier to their use in next-generation electronics.

Two discoveries could provide a simple and effective way to “stencil” high-quality 2D materials in precise locations and overcome a barrier to their use in next-generation electronics.