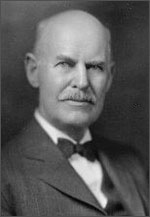

Edward Goodrich Acheson (1856-1931), one of the charter members of ECS, is best known for having invented and commercialized carborundum, an artificial graphite.

Biography

Acheson was born in southwestern Pennsylvania and raised its coal fields. At the age of 16, after his father died, he left school to help support his family. Nevertheless, Acheson devoted his nights to the scientific endeavors, especially electrical experiments.

In 1880, Acheson attempted to sell a battery of his own invention to Thomas Edison, who ended up hiring him to assist with his research. He experimented with creating a conducting carbon that Edison could use in his electric light bulbs.

After working for Edison for four years, Acheson left his employ to become an independent inventor. In 1891, Acheson acquired access to an electric

generating plant and attempted to use electric heat to impregnate clay with carbon. What resulted from this experiment was his discovery of a crystalline substance that had value as an abrasive, which Acheson named “carborundum” (also known as silicon carbide).

In 1894, he established the Carborundum Company in Monongahela City, Pennsylvania, which created grinding wheels, whet stones, knife sharpeners, and powdered abrasives. Later, Acheson used his electric furnace to produce artificial graphite, which he commercialized, discovering that various organic substances allowed colloidal suspension of particles of graphite mixed in oil or water.

Acheson received 70 patents related to abrasives, graphite products, reduction of oxides, and refractories. ECS awarded him the first Acheson Award, named in his honor, in 1931.

ECS senior vice president and professor at the University of Texas at Arlington,

ECS senior vice president and professor at the University of Texas at Arlington,