A team of researchers has created a new material that could be used in microscopic sensors, also known as microelectromechanical systems [MEMS], for devices that are part of the Internet of Things.

A team of researchers has created a new material that could be used in microscopic sensors, also known as microelectromechanical systems [MEMS], for devices that are part of the Internet of Things.

The technological future of everything from cars and jet engines to oil rigs, along with the gadgets, appliances, and public utilities comprising the Internet of Things will depend on these kinds of microscopic sensors. These sensors are mostly made of the material silicon, however, which has its limits.

“For a number of years we’ve been trying to make MEMS out of more complex materials” that are more resistant to damage and better at conducting heat and electricity, says materials scientist and mechanical engineer Kevin J. Hemker of Johns Hopkins University’s Whiting School of Engineering.

Most MEMS devices have internal structures that are smaller than the width of strand of human hair and are shaped out of silicon. These devices work well in average temperatures, but even modest amounts of heat—a couple hundred degrees—causes them to lose their strength and their ability to conduct electronic signals. Silicon is also very brittle and prone to break.

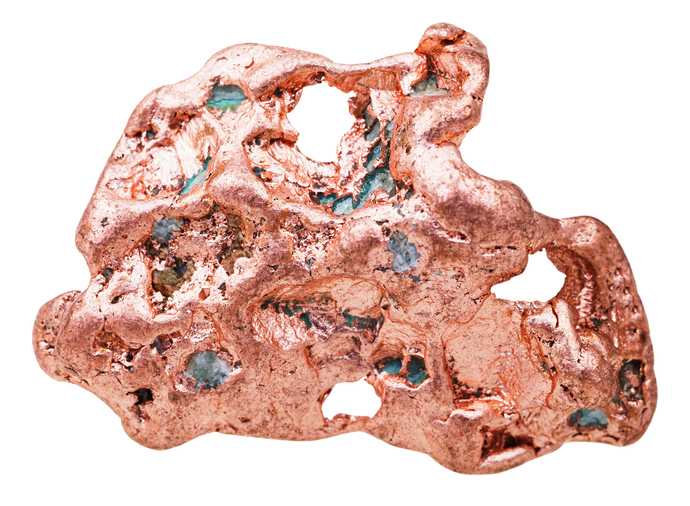

Researchers from MIT have developed a new way to extract copper by separating the commercially valuable metal from sulfide minerals in one step without harmful byproducts. The goal of this new process is to simplify metal production, thereby eliminating harmful byproducts and driving down costs.

Researchers from MIT have developed a new way to extract copper by separating the commercially valuable metal from sulfide minerals in one step without harmful byproducts. The goal of this new process is to simplify metal production, thereby eliminating harmful byproducts and driving down costs. Earth’s climate is changing rapidly. We know this from billions of observations, documented in thousands of journal papers and texts and

Earth’s climate is changing rapidly. We know this from billions of observations, documented in thousands of journal papers and texts and

In an effort to develop a more affordable, plentiful alternative to lithium-ion batteries, researchers from Purdue University are pursuing rechargeable potassium based batteries, demonstrating a way to derive carbon for battery electrodes from old tires.

In an effort to develop a more affordable, plentiful alternative to lithium-ion batteries, researchers from Purdue University are pursuing rechargeable potassium based batteries, demonstrating a way to derive carbon for battery electrodes from old tires.

Nomination Deadline: August 1, 2017

Nomination Deadline: August 1, 2017 Nomination Deadline: September 1, 2017

Nomination Deadline: September 1, 2017 Science is messy, but it doesn’t have to be dirty.

Science is messy, but it doesn’t have to be dirty.