A new kind of lithium sulfur battery could be more efficient, less expensive, and safer than currently available lithium batteries.

A new kind of lithium sulfur battery could be more efficient, less expensive, and safer than currently available lithium batteries.

“We demonstrated this method in a coin battery,” says Donghai Wang, associate professor of mechanical engineering at Penn State. “But, I think it could eventually become big enough for cell phones, drones, and even bigger for electric vehicles.”

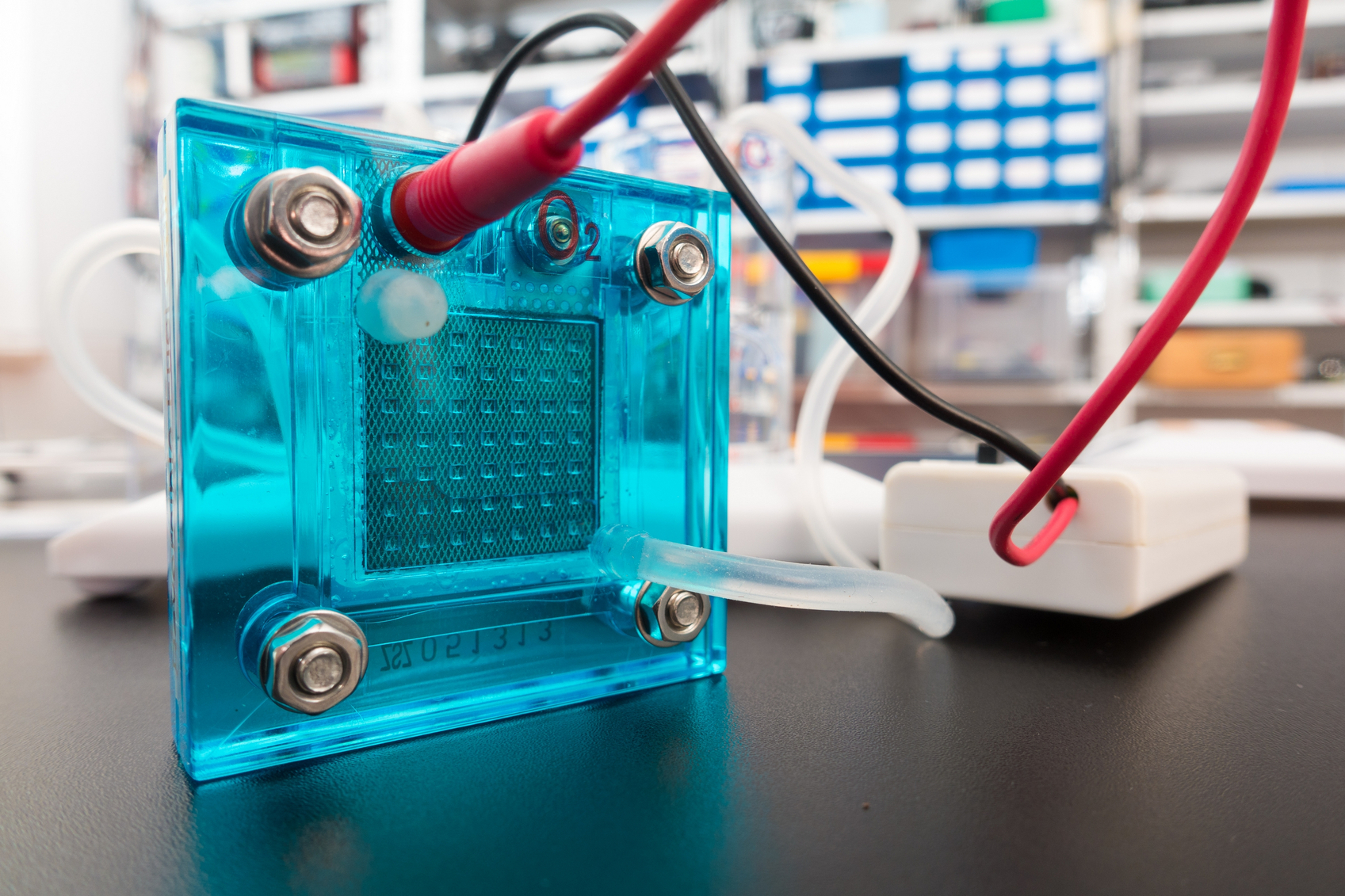

Lithium sulfur batteries should be a promising candidate for the next generation of rechargeable batteries, but they are not without problems. For lithium, the efficiency in which charge transfers is low, and, lithium batteries tend to grow dendrites—thin branching crystals—when charging that do not disappear when discharged.

The researchers examined a self-formed, flexible hybrid solid-electrolyte interphase layer that is deposited by both organosulfides and organopolysulfides with inorganic lithium salts. The researchers report that the organic sulfur compounds act as plasticizers in the interphase layer and improve the mechanical flexibility and toughness of the layer. The interphase layer allows the lithium to deposit without growing dendrites. The Coulombic efficiency is about 99 percent over 400 recharging discharging cycles.

Ask people to name the most famous historical woman of science and their answer will likely be: Madame Marie Curie. Push further and ask what she did, and they might say it was something related to

Ask people to name the most famous historical woman of science and their answer will likely be: Madame Marie Curie. Push further and ask what she did, and they might say it was something related to  A new sodium-based battery can store the same amount of energy as a state-of-the-art lithium ion at a substantially lower cost.

A new sodium-based battery can store the same amount of energy as a state-of-the-art lithium ion at a substantially lower cost. A new flexible, paper-based supercapacitor could power wearable electronics.

A new flexible, paper-based supercapacitor could power wearable electronics. A closer look at catalysts is giving researchers a better sense of how these atom-thick materials produce hydrogen.

A closer look at catalysts is giving researchers a better sense of how these atom-thick materials produce hydrogen. Tech Highlights was prepared by David Enos and Mike Kelly of Sandia National Laboratories, Colm Glynn and David McNulty of University College Cork, Ireland, Zenghe Liu of Verily Life Science, and Donald Pile of Rolled-Ribbon Battery Company. This article was originally published in the

Tech Highlights was prepared by David Enos and Mike Kelly of Sandia National Laboratories, Colm Glynn and David McNulty of University College Cork, Ireland, Zenghe Liu of Verily Life Science, and Donald Pile of Rolled-Ribbon Battery Company. This article was originally published in the  Engineers working to make solar cells more cost effective ended up finding a method for making sonar-like collision avoidance systems in self-driving cars.

Engineers working to make solar cells more cost effective ended up finding a method for making sonar-like collision avoidance systems in self-driving cars. The development of prosthetics has changed many lives, providing mobility options and allowing for more active lives. But all artificial limbs aren’t perfect. Some can be painful, difficult to use, and lead to possible skin infections. The Office of Naval Research is looking to change that, providing new options for those in need of artificial limbs.

The development of prosthetics has changed many lives, providing mobility options and allowing for more active lives. But all artificial limbs aren’t perfect. Some can be painful, difficult to use, and lead to possible skin infections. The Office of Naval Research is looking to change that, providing new options for those in need of artificial limbs. Just a few months ago, business magnate Elon Musk announced that he would spearhead an effort to build the

Just a few months ago, business magnate Elon Musk announced that he would spearhead an effort to build the  Submit your manuscripts to the Journal of The Electrochemical Society (JES)

Submit your manuscripts to the Journal of The Electrochemical Society (JES)