While working on a unique lithium-germanide battery, Pacific Northwest National Laboratory (PNNL) researchers knew something was happening inside the battery to dramatically increase its energy storage capacity, but they couldn’t see it. With no way to analyze the reaction occurring, the researchers could not understand the process. In order to solve the problem, the researchers developed a novel nuclear magnetic resonance (NMR) technique to allow insight and understanding of the electrochemical reactions taking place in the battery. Essentially, they have developed an NMR “camera.”

In the end, this leaves the scientists with not only a novel lithium-germanide battery with a distinctly high energy density, but also an NMR device that can be used to examine reactions as they happen inside the battery.

This from PNNL:

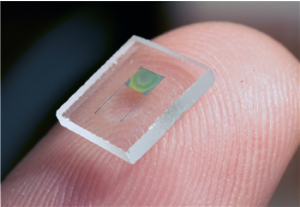

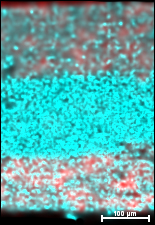

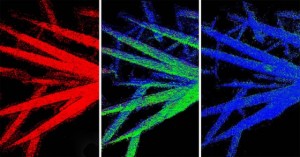

By using the NMR process to look inside the battery and observe this reaction as it happened, the scientists found a way to protect the germanium from expanding and becoming ineffective after it takes on lithium. The secret proved to be forming the germanium into tiny “wires” and encasing them in small, protective carbon tubes to limit the expansion. This technique significantly stabilizes battery performance. Without embedding germanium in carbon tubes, a battery performs well for a few charging-discharging cycles, but fades rapidly after that. Using the “core-shell” structure, however, the battery can be discharged and charged thousands of times.