Luis Fernando Arenas

Luis Fernando Arenas

Humboldt Research Fellow

Institute of Chemical and Electrochemical Process Engineering

Research Center for Energy Storage Technologies

Technische Universität Clausthal University, Germany

Date: July 20, 2022

Time: 1000h ET

Sponsors: Hiden Analytical, The Royal Society of Chemistry, Waters-TA Instruments

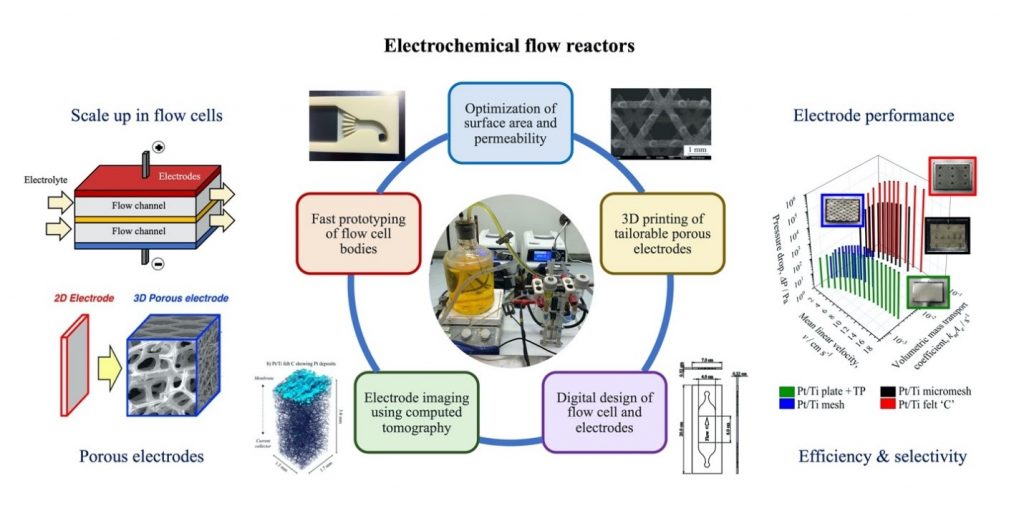

Most industrial operations based on electrode reactions involve electrochemical flow reactors. Applications include inorganic/organic electrosynthesis, water electrolysis, environmental remediation and energy storage. The versatile “filter-press” flow reactor offers a controlled reaction environment for processing large volumes of electrolytes. Meanwhile, porous electrodes improve the productivity and efficiency of electrochemical reactors by enhancing surface area and mass transport. Metal and carbon materials are used as meshes, foams, and felts, often coated with catalysts. Under forced flow, the permeability of electrodes becomes important for energy efficiency and balance of plant design. A compromise must be found between the electrode surface area and permeability of porous electrodes.

This presentation highlights the characteristics and benefits of flow cells through the development of Pt/Ti electrodes for flow batteries and the optimization of 3D printed electrodes. After showing the advantages of computed tomography for the study of porous materials, their performance is quantified by the volumetric mass transport coefficient and their permeability to fluids. The importance of tomography parameters to the analysis of surface area and volume is exemplified by reticulated vitreous carbon. The concept of tailorable, 3D printed electrodes for electrochemical reactors is introduced. Different geometries are considered. Future progress in 3D printed electrodes for prototype production, model validation, and quick availability of specialized devices is discussed.

Benefits of attending the webinar

Participants learn about:

- Importance and characteristics of electrochemical flow reactors;

- Advantages and requirements of porous electrodes in flow cells;

- Possibilities of additive manufacturing in electrochemical engineering.

Dr. Luis Fernando Arenas

Dr. Luis Fernando Arenas is a Humboldt Research Fellow at Technische Universität Clausthal where he collaborates with Prof. Thomas Turek on the development of organic flow batteries. He is also a Visiting Academic at the University of Southampton (UOS), UK, and Early Career Representative at the Electrochemical Technology Group of the Society of Chemical Industry, UK. After completing a BSc in Chemistry and MSc degree in Chemical Technology at the Universidad Autónoma de Coahuila, Mexico, he pursued doctoral studies in Electrochemical Engineering at UOS. There he focused on zinc-cerium flow batteries under the supervision of Profs. Carlos Ponce de León and Frank C. Walsh, graduating in 2017. He was a Research Fellow at UOS, developing PEM fuel cells and electrochemical hydrogen pumps (2017-2019). Dr. Arenas has also been a private contractor for the development of new organic- and electrodialysis-based flow batteries for INEEL (Instituto Nacional de Electricidad y Energías Limpias) and consultant for the chlor-alkali industry (2019-2021). Additional interests include 3D printed electrodes, computed tomography, electrodeposition of noble metals, porous electrodes, and sustainable electrochemical engineering. He became an ECS member in 2014. His research has resulted in 31 peer-reviewed papers, four book chapters, six conference papers, and 17 posters, as well as 40 talks, seven of them by invitation (Google Scholar: 1018 citations, h-index 17). Dr. Arenas received the 2019 Schwäbisch Gmünd Prize for Young Scientists for excellence in electrochemical surface technology.

Dr. Luis Fernando Arenas is a Humboldt Research Fellow at Technische Universität Clausthal where he collaborates with Prof. Thomas Turek on the development of organic flow batteries. He is also a Visiting Academic at the University of Southampton (UOS), UK, and Early Career Representative at the Electrochemical Technology Group of the Society of Chemical Industry, UK. After completing a BSc in Chemistry and MSc degree in Chemical Technology at the Universidad Autónoma de Coahuila, Mexico, he pursued doctoral studies in Electrochemical Engineering at UOS. There he focused on zinc-cerium flow batteries under the supervision of Profs. Carlos Ponce de León and Frank C. Walsh, graduating in 2017. He was a Research Fellow at UOS, developing PEM fuel cells and electrochemical hydrogen pumps (2017-2019). Dr. Arenas has also been a private contractor for the development of new organic- and electrodialysis-based flow batteries for INEEL (Instituto Nacional de Electricidad y Energías Limpias) and consultant for the chlor-alkali industry (2019-2021). Additional interests include 3D printed electrodes, computed tomography, electrodeposition of noble metals, porous electrodes, and sustainable electrochemical engineering. He became an ECS member in 2014. His research has resulted in 31 peer-reviewed papers, four book chapters, six conference papers, and 17 posters, as well as 40 talks, seven of them by invitation (Google Scholar: 1018 citations, h-index 17). Dr. Arenas received the 2019 Schwäbisch Gmünd Prize for Young Scientists for excellence in electrochemical surface technology.

Learn more about upcoming ECS Webinars and view our previous webinar recordings.

We thank our webinar sponsors who make these complimentary programs possible.

Interested in presenting in the ECS Webinar Series? Email your presentation title and abstract to education@electrochem.org for consideration.