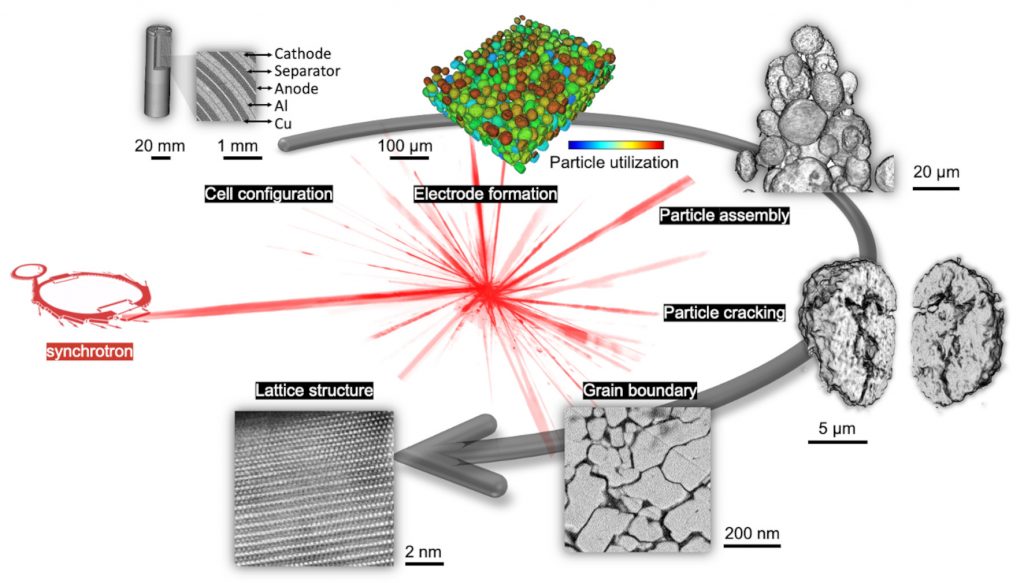

The Electrochemical Society hosted Dr. Yijin Liu’s live webinar, “A micro-to-nano zoom through a real-world battery with x-ray vision,” on May 17, 2023. Dr. Liu took audience questions during a live Question and Answer session at the end of the presentation. Kindly, he answered, in writing, questions not answered during the broadcast. See his responses below.

The Electrochemical Society hosted Dr. Yijin Liu’s live webinar, “A micro-to-nano zoom through a real-world battery with x-ray vision,” on May 17, 2023. Dr. Liu took audience questions during a live Question and Answer session at the end of the presentation. Kindly, he answered, in writing, questions not answered during the broadcast. See his responses below.

NOTE: Registration is required to view the webinar.

Q&A

How does the x-ray dose affect the studies?

X-rays interact with matter in several different ways. On the one hand, these sample-beam interactions carry useful information regarding the sample’s physical and chemical properties. On the other hand, incident x-rays could induce some changes to the sample, causing artifacts in the experimental data.

Concerns about radiation doses are often highlighted in biological, medical, and clinical applications. It is useful to point out that it could also play a significant role in battery research. For example, a strong, focused x-ray beam from a synchrotron could lead to local temperature rise, causing bubble formation in the liquid electrolyte. The sample deformation and sometimes, local deactivation caused by this effect, have nothing to do with the battery’s intrinsic behavior.

In practice, we often need to estimate the maximum tolerable dose and dose rate for a given sample and then, accordingly, manage the experiment properly .

What are the critical requirements for x-ray techniques for today’s battery R&D and manufacturing?

X-ray metrology is an active field. A lot of efforts have been devoted to improving the resolution, sensitivity, and efficiency of various x-ray characterization modalities. In my opinion, for battery R&D, and especially for application in battery manufacturing, the main challenge lies with the required throughput. For this application, key technical questions include how we can increase experimental efficiency; how we can quickly extract useful information from the raw data; how we can work with noisy data. The integration of expertise in x-ray instrumentation, battery chemistry, and data science is an important path forward.

Perspectives on the use of AI methods for the presented studies?

It is important for us to formulate a coherent integration of expertise in different areas, including AI (artificial intelligence) and ML (machine learning). In one of the case studies that I presented in the talk, we leverage the algorithm developments in computer vision and modify the existing method for our application [DOI: 10.1126/science.abm896]. I believe that this is an effective approach to avoid unnecessary redundant developments.

A smart implementation of AI and ML tools could significantly improve the efficiency of our research. However, they shall be used with caution. Review, validation, and benchmarking need to be carried out carefully. In my view, AI/ML tools can help to capture features and trends in the data, but the scientific interpretation still relies on domain experts.

What are the limiting factors for further improving x-ray imaging resolution and throughput?

Today’s x-ray microscopy techniques can offer a wide range of spatial resolutions from a few nm to mm-scale. The practical limits in resolution and throughput are set by the source brightness and quality of the x-ray optics.

Tremendous resources and efforts have been invested in this. For example, billion-dollar facilities of synchrotrons and free electron lasers are being built and upgraded, offering unprecedented scientific opportunities. Their limited availability, however, makes broad adoption difficult. Compact laboratory systems have also been developed. At the same time, the developments in nanofabrication techniques are improving our ability to make fine x-ray optics. In addition to the instrumentation developments, the leverage of modern computing methods is a notable trend in this field.

What is the difference between synchrotron and in situ measurement?

Synchrotrons are large-scale, billion-dollar facilities that generate x-rays with high brilliance and quality. Scientists utilize synchrotrons as x-ray sources for various studies.

“In situ” means “in its original place.” When we talk about in situ experiments for battery characterization, we refer to studying battery materials/components inside a functional battery cell—as opposed to taking the cell apart and then looking at the recovered materials/components.

Synchrotrons provide high quality x-ray beams and make a lot of in situ experiments easier.

Can you perform x-ray measurements of LIB cells at different temperatures?

Yes. We perform x-ray characterization of LIBs (lithium ion batteries) under different temperatures, which is both of fundamental interest and practical significance. My research group has conducted x-ray characterization of battery materials over a wide temperature range, from below -150 °C [DOI: 10.1002/aenm.202102122] to above 500 °C [DOI: 10.1016/j.mattod.2019.11.009].

One of the main advantages of x-rays is their strong penetration capability, which makes it possible to investigate samples’ internal structure in a “non-invasive” manner. The same characteristics make it possible to study a sample inside a sample chamber without the need to open it. Scientists often construct sample chambers with controllable environments, e.g., temperature, pressure, gas atmosphere, etc. These are often tailor-made for different applications.

Please highlight how x-ray generated data are prepared for training ML models.

Generally speaking, raw data from an x-ray experiment must go through a data curation process involving many steps before it starts to reflect specific meanings for interpretation. Many algorithms and software have been developed for data curation for different experimental modalities. State-of-the-art experimental developments, however, have dramatically increased the data rate and, in many cases, necessitate the adoption of ML tools. While some of the common practices in data curation still need to be followed, researchers are making efforts to streamline this process. Automation, robustness, and accuracy are important when it comes to high-throughput data reduction.

Specific to battery imaging data analysis using ML models, we developed algorithms for image denoising, normalization, reconstruction, registration, segmentation, and statistical analysis. Depending on which ML models are used, sometimes manual segmentation or annotation is needed for preparing the training set.

Are there also limitations in using x-ray-characterizations? Can you apply x-ray-based methods for any material and electrolyte composition? Can you discuss some of the limitations for observing degradation mechanisms like dendrite formation or surface passivation?

X-ray characterization is a terminology that covers a lot of content. It could involve the use of x-rays of different energy (soft x-rays to hard x-rays) and the implementation of different experimental modalities (diffraction, spectroscopy, imaging, and their hybrids). There are pros and cons for each specific modality.

For example, soft x-ray spectroscopy has excellent chemical sensitivity to some processes of interest (for example, surface lattice reconstruction and passivation), but it must usually be conducted in a vacuum chamber or with a specifically designed environmental cell. Hard x-ray tomography/laminography can be applied to large-format, industry-relevant cells, but they face challenges in revealing small and weak-absorbing features.

A carefully designed multi-modal approach could be very helpful.

Referencing slide 24: What type of ML segmentation was used?

I refer to this open access article [DOI: 10.1038/s41467-020-16233-5] for more details on the segmentation method. Our source code and instructions are also freely accessible at our GitHub repository [https://github.com/YijinLiu-Lab/LIBNet].

Because of the geometry of pouch cells, what is the best resolution you can get in them with XCT (x-ray computed tomography)?

In our experiment, we experienced significant image artifact when reconstructing tomography data of a pouch cell with high aspect ratio in its geometry. Although the pixel size can still be small (at sub-micron level), the artifacts make the effective resolution a lot worse. Therefore, we utilized a laminography approach, which provided sub-micron reconstruction with high fidelity. I refer to this article for more details [DOI: 10.1073/pnas.2203199119].

Please shine a light on how holotomography is different from normal tomography?

When an x-ray beam penetrates through a sample, it gets absorbed, refracted, and scattered. These processes carry different information about the sample. Normal tomography senses the degree of x-ray attenuation, which is straightforward to measure. However, when dealing with weak absorbing components of the sample (e.g., carbon and binder in a battery electrode or a soft tissue in a biological sample), the absorption contrast is insufficient for generating a nice image.

To address this challenge, one way to improve image quality is to utilize so-called phase contrast, which senses phase shift instead of absorption. Holotomography is one of the methods for doing this. By implementing an imaging setup with an x-ray source with decent coherence, we can convert the sample-induced phase shift into measurable intensity variations on the detector. The raw data is full of fringes and they are not good-looking images. But after proper phase retrieval calculations, a nice image with good sensitivity to both strong and weak absorbing features can be obtained.

It is useful to mention that phase contrast can be achieved through different approaches. I refer to this review article for more details [DOI:10.1088/0022-3727/46/49/494001].

How feasible are the techniques you have shown today for implementing in next-generation chemistries (i.e., LFP, Li-S, etc.)?

X-ray microscopy is quite broadly applicable. Here I refer to a few examples of using x-ray microscopy to study LFP [DOI:10.1088/0022-3727/46/49/494001], Li-S [DOI:10.1021/ja2121926], solid state batteries [DOI:10.1038/s41563-020-00903-2]. I also recommend this comprehensive review article on x-ray tomographic characterization of various battery systems[DOI:10.1038/s41565-022-01081-9].

Can you locate specific defects leading to short circuits, etc., in x-ray topographic imaging?

A short answer is yes. We can detect many different types of cell defects that could lead to the formation of internal short circuits. However, a lot of work is needed to quantitatively associate these defects with a specific failure mode with statistical significance.

Have you ever applied 3D spectroscopy/tomography to solid state batteries to reveal the real-time charging/discharging status of cathode materials? Please comment on what kind of potential challenges may occur?

The study of solid state batteries is an important topic in this field. Here I refer to two recent tomographic studies of solid state electrolyte [DOI:10.1038/s41563-020-00903-2] and [DOI:10.1038/s41563-021-00967-8].

For the cathode in a solid state battery, the system is further complicated as the arrangement of active materials and electrolyte (both are in solid state) will critically affect the lithium diffusion pathway and thus the charge heterogeneity. Unlike a cell with liquid electrolyte that could freely infiltrate any open space connected by the pore network, the solid state electrolyte does not have such capability. Therefore, micromorphology design becomes very critical. I refer to two papers in this area for more detailed discussions [DOI:10.1016/j.joule.2021.05.017] and [DOI:10.1093/nsr/nwac272].

About the discharging cycles for Li-ion batteries, will there be any oxidized deposits which might disturb the overall efficiency of the battery during charging cycles?

Cathode dissolution and precipitation on the anode is one of the common mechanisms for capacity fade. The deposited metals on the anode side have inhomogeneous distribution and are in various chemical states. This will certainly affect the cell behavior. One of the mitigation approaches is to suppress this effect through liquid electrolyte engineering with additives [DOI:10.1038/s41560-022-01020-x (2022)].

What is the effect of impurities present on electrode surfaces over the charging cycles?

In one of our studies that focuses on the defects in commercial cells [DOI:10.1016/j.xcrp.2021.100554], we observed that the existence of impurity particles in the cathode leads to 1) a more severe surface reconstruction from layered structure to spinel and/or rock salt phases and 2) a partial deactivation of the corresponding local regions. This observation is based on a limited amount of data from a few cells that we studied. In addition, depending on the composition and morphology of the impurity particles, it could potentially lead to detrimental effects including ununiform metal dissolution/precipitation and internal soft short.

These impurities and the above discussed processes are often sparsely and randomly distributed. It is therefore challenging to study. Cells with purposely induced defects/impurities at known locations might be useful to conduct a thorough study on the impacts of the impurities.

Can you comment on characterizing Li-metal anode with x-ray, like measuring the Li dendrite growth during charging? How about radiation damage?

Li-metal is weak absorbing and is difficult to detect using hard x-rays. Conventional attenuation-based x-ray imaging has limitations in dealing with this. However, as I discussed above, when an x-ray beam penetrates through a sample, it gets absorbed, refracted, and scattered. These processes carry different information on the sample. One way of improving the image quality is to utilize so-called phase contrast, which senses the phase shift instead of absorption.

In practice, the image we record using an x-ray camera often has contributions from multiple sample-beam interaction processes, including absorption, refraction, and scattering. For example, when the detector is placed at a distance from the sample, there is an edge enhancement effect, which becomes useful for detecting some of the weak-absorbing features, including lithium. I refer to a few published papers as examples: Li in solid state electrolyte [DOI:10.1038/s41563-021-00967-8], Li whisker on cathode surface upon heating [DOI:10.1039/C8TA08973F], Li plating in a pouch cell [DOI:10.1073/pnas.2203199119].

For the discussion of x-ray dose effect, I refer to the answer to the first question above.

What are the factors in deciding the cell design?

The cell design and choice of material are often determined by the end application. For example, in consumer electronics, due to the desired compact design, LiCoO2 is the dominating cathode choice. This is because of LCO’s superior volumetric energy density. In electric vehicle applications, we see a trend toward large-format cylindrical cells because the form factor can impact the energy density and cell longevity. In practice, the optimization of cell designs is often through trial and error. Advanced characterization coupled with theoretical modeling could help us to improve efficiency and quality.

Would complication of the components, such as binders, conducting agents, or electrolytes, affect x-ray analysis?

While a lot of the results I presented in this talk are based on x-ray microscopy, as I have discussed above, x-ray analysis can be carried out in several different modalities which have sensitivities to different material properties. This offers opportunities to investigate the roles of different cell components. I refer to this comprehensive review article for more details on using various synchrotron characterization methods for battery R&D [DOI:10.1021/acs.chemrev.7b00007].