Researchers from Oregon State university have developed the first battery that uses only hydronium ions as the charge carrier, which the team believes could yield promising results for the future of sustainable energy storage.

Researchers from Oregon State university have developed the first battery that uses only hydronium ions as the charge carrier, which the team believes could yield promising results for the future of sustainable energy storage.

Particularly, the researchers are interested in the area of stationary storage. This type of energy storage primarily refers to on-grid storage to harness power from intermittent sources, such as wind or solar, for later use in general distribution. Stationary energy storage is vital for the energy landscape to transition to more renewable types of energy because it will allow the electrical grid to continue to function when the sun goes down and the wind stops blowing.

This from Oregon State University:

Hydronium, also known as H3O+, is a positively charged ion produced when a proton is added to a water molecule. Researchers in the OSU College of Science have demonstrated that hydronium ions can be reversibly stored in an electrode material consisting of perylenetetracarboxylic dianhydridem, or PTCDA.

A new paper published in the Journal of The Electrochemical Society, “

A new paper published in the Journal of The Electrochemical Society, “ In an effort to develop an eco-friendly battery, researchers from Ulsan National Institute of Science and Technology (UNIST) have created a battery that can store and produce electricity by using seawater.

In an effort to develop an eco-friendly battery, researchers from Ulsan National Institute of Science and Technology (UNIST) have created a battery that can store and produce electricity by using seawater. A battery made with urea, commonly found in fertilizers and mammal urine, could provide a low-cost way of storing energy produced through solar power or other forms of renewable energy for consumption during off hours.

A battery made with urea, commonly found in fertilizers and mammal urine, could provide a low-cost way of storing energy produced through solar power or other forms of renewable energy for consumption during off hours. Most of today’s batteries are made up of two solid layers, separated by a liquid or gel electrolyte. But some researchers are beginning to move away from that traditional battery in favor of an all-solid-state battery, which some researchers believe could enhance battery energy density and safety. While there are many barriers to overcome when pursing a feasible all-solid-state battery, researchers from MIT believe they are headed in the right direction.

Most of today’s batteries are made up of two solid layers, separated by a liquid or gel electrolyte. But some researchers are beginning to move away from that traditional battery in favor of an all-solid-state battery, which some researchers believe could enhance battery energy density and safety. While there are many barriers to overcome when pursing a feasible all-solid-state battery, researchers from MIT believe they are headed in the right direction.

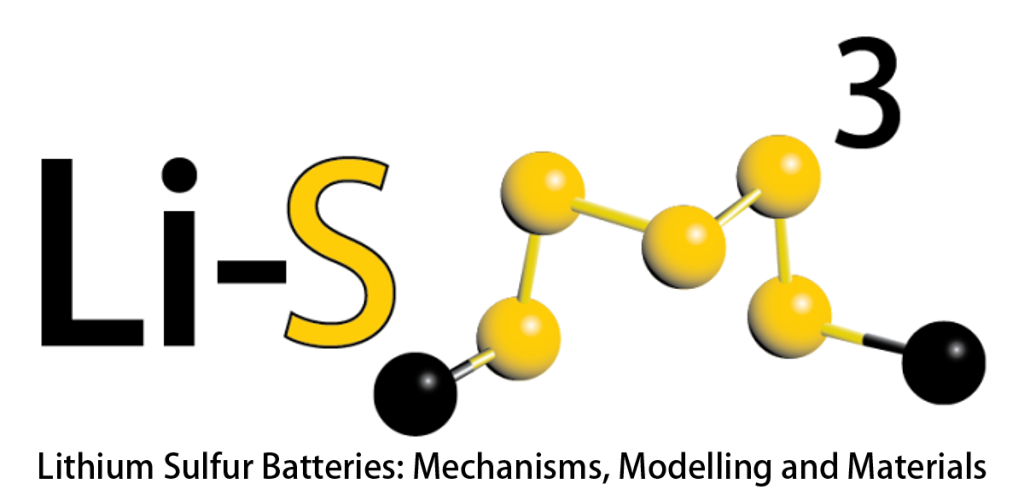

Lithium-ion batteries supply billions of portable devices with energy. While current Li-ion battery designs may be sufficient for applications such as smartphones and tablets, the rise of electric vehicles and power storage systems demands new battery technology with new electrode materials and electrolytes.

Lithium-ion batteries supply billions of portable devices with energy. While current Li-ion battery designs may be sufficient for applications such as smartphones and tablets, the rise of electric vehicles and power storage systems demands new battery technology with new electrode materials and electrolytes.