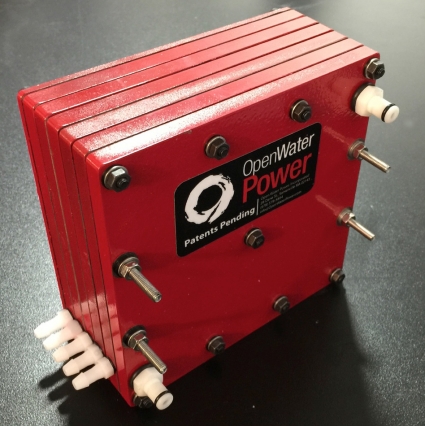

Image: Open Water Power

Unpiloted underwater vehicles (UUVs) are used for a wide array of tasks, including exploring ship wreckage, mapping the ocean floor, and military applications. Now, a team from MIT has developed an aluminum-water power system that will allow UUVs to become safer, more durable, and have ten times more range compared to UUVs powered by lithium-ion batteries.

“Everything people want to do underwater should get a lot easier,” says Ian Salmon Mckay, co-inventor of the device. “We’re off to conquer the oceans.”

The aluminum-water power system is a direct response to lithium-ion batteries, which have a limited energy density causing service ships to chaperone UUVs while at sea, recharging the batteries when necessary. Additionally, UUV lithium-ion batteries have to be encased in expensive metal pressure vessels, making the battery both short-lived and pricey for use in UUVs.

This from MIT:

In contrast, [Open Water Power’s] power system is safer, cheaper, and longer-lasting. It consists of a alloyed aluminum, a cathode alloyed with a combination of elements (primarily nickel), and an alkaline electrolyte that’s positioned between the electrodes.

A new study describes the mechanics behind an early key step in artificially activating carbon dioxide so that it can rearrange itself to become the liquid fuel ethanol.

A new study describes the mechanics behind an early key step in artificially activating carbon dioxide so that it can rearrange itself to become the liquid fuel ethanol. In an effort to increase security on airplanes, the U.S. government is considering expanding a ban on lithium-ion based devices from cabins of commercial flights, opting instead for passengers to transport laptops and other electronic devices in their checked luggage in the cargo department. However, statistics from the Federal Aviation Administration suggest that storing those devices in the cargo area

In an effort to increase security on airplanes, the U.S. government is considering expanding a ban on lithium-ion based devices from cabins of commercial flights, opting instead for passengers to transport laptops and other electronic devices in their checked luggage in the cargo department. However, statistics from the Federal Aviation Administration suggest that storing those devices in the cargo area  In its first “

In its first “ In 2016,

In 2016,  The

The  The consumer demand for seamless, integrated technology is on the rise, and with it grows the Internet of Things, which is expected to grow to a

The consumer demand for seamless, integrated technology is on the rise, and with it grows the Internet of Things, which is expected to grow to a  Researchers from Columbia University School of Engineering and Applied Science recently developed a method that could result in safer, longer-lasting, bendable lithium-ion batteries. To do this, the team applied ice-templating to control the structure of the solid electrolyte for lithium-ion batteries.

Researchers from Columbia University School of Engineering and Applied Science recently developed a method that could result in safer, longer-lasting, bendable lithium-ion batteries. To do this, the team applied ice-templating to control the structure of the solid electrolyte for lithium-ion batteries.