ECS is hosting a series of webinars presented by distinguished speakers this June. Join us! Speakers include Harry Atwater from the California Institute of Technology, Arumugam Manthiram from the University of Texas at Austin, and Paul Kenis from the University of Illinois at Urbana-Champaign. Topics include batteries, energy, carbon, and more. Considering attending? Learn more about what you can expect to hear about from our presenters! (more…)

ECS is hosting a series of webinars presented by distinguished speakers this June. Join us! Speakers include Harry Atwater from the California Institute of Technology, Arumugam Manthiram from the University of Texas at Austin, and Paul Kenis from the University of Illinois at Urbana-Champaign. Topics include batteries, energy, carbon, and more. Considering attending? Learn more about what you can expect to hear about from our presenters! (more…)

A new study describes the mechanics behind an early key step in artificially activating carbon dioxide so that it can rearrange itself to become the liquid fuel ethanol.

A new study describes the mechanics behind an early key step in artificially activating carbon dioxide so that it can rearrange itself to become the liquid fuel ethanol.

Solving this chemical puzzle may one day lead to cleaner air and renewable fuel.

The scientists’ ultimate goal is to convert harmful carbon dioxide (CO2) in the atmosphere into beneficial liquid fuel. Currently, it is possible to make fuels out of CO2—plants do it all the time—but researchers are still trying to crack the problem of artificially producing the fuels at large enough scales to be useful.

Theorists at Caltech used quantum mechanics to predict what was happening at atomic scales, while experimentalists at the Department of Energy’s (DOE) Lawrence Berkeley National Lab (Berkeley Lab) used X-ray studies to analyze the steps of the chemical reaction.

“One of our tasks is to determine the exact sequence of steps for breaking apart water and CO2 into atoms and piecing them back together to form ethanol and oxygen,” says William Goddard professor of chemistry, materials science, and applied physics, who led the Caltech team. “With these new studies, we have better ideas about how to do that.”

Chemists have engineered a molecule that uses light or electricity to convert carbon dioxide into carbon monoxide—a carbon-neutral fuel source—more efficiently than any other method of “carbon reduction.”

Chemists have engineered a molecule that uses light or electricity to convert carbon dioxide into carbon monoxide—a carbon-neutral fuel source—more efficiently than any other method of “carbon reduction.”

“If you can create an efficient enough molecule for this reaction, it will produce energy that is free and storable in the form of fuels,” says study leader and Liang-shi Li, associate professor in the chemistry department at Indiana University Bloomington. “This study is a major leap in that direction.”

Burning fuel—such as carbon monoxide—produces carbon dioxide and releases energy. Turning carbon dioxide back into fuel requires at least the same amount of energy. A major goal among scientists has been decreasing the excess energy needed.

This is exactly what Li’s molecule achieves: requiring the least amount of energy reported thus far to drive the formation of carbon monoxide. The molecule—a nanographene-rhenium complex connected via an organic compound known as bipyridine—triggers a highly efficient reaction that converts carbon dioxide to carbon monoxide.

The ability to efficiently and exclusively create carbon monoxide is significant due to the molecule’s versatility.

With hydrogen power stations in California, a new Japanese consumer car and portable hydrogen fuel cells for electronics, hydrogen as a zero emission fuel source is now finally becoming a reality for the average consumer. When combined with oxygen in the presence of a catalyst, hydrogen releases energy and bonds with the oxygen to form water.

With hydrogen power stations in California, a new Japanese consumer car and portable hydrogen fuel cells for electronics, hydrogen as a zero emission fuel source is now finally becoming a reality for the average consumer. When combined with oxygen in the presence of a catalyst, hydrogen releases energy and bonds with the oxygen to form water.

The two main difficulties preventing us from having hydrogen power everything we have are storage and production. At the moment, hydrogen production is energy-intensive and expensive. Normally, industrial production of hydrogen requires high temperatures, large facilities and an enormous amount of energy. In fact, it usually comes from fossil fuels like natural gas – and therefore isn’t actually a zero-emission fuel source. Making the process cheaper, efficient and sustainable would go a long way toward making hydrogen a more commonly used fuel.

An excellent – and abundant – source of hydrogen is water. But chemically, that requires reversing the reaction in which hydrogen releases energy when combining with other chemicals. That means we have to put energy into a compound, to get the hydrogen out. Maximizing the efficiency of this process would be significant progress toward a clean-energy future.

One method involves mixing water with a helpful chemical, a catalyst, to reduce the amount of energy needed to break the connections between hydrogen and oxygen atoms. There are several promising catalysts for hydrogen generation, including molybdenum sulfide, graphene and cadmium sulfate. My research focuses on modifying the molecular properties of molybdenum sulfide to make the reaction even more effective and more efficient.

Making hydrogen

Hydrogen is the most abundant element in the universe, but it’s rarely available as pure hydrogen. Rather, it combines with other elements to form a great many chemicals and compounds, such as organic solvents like methanol, and proteins in the human body. Its pure form, H₂, can used as a transportable and efficient fuel.

Globally, carbon dioxide is the number one contributor to harmful greenhouse gas emissions. These emissions accelerate climate change, leading to such devastating effects as rising sea levels that can dislocate families and radical local climates that hurt food production levels.

But what if we could turn those harmful emissions into useable fuels through a simple, one-step process?

Researchers have proven that through a process combining concentrated light, heat, and high pressure, carbon dioxide and water could be directly converted into usable liquid hydrocarbon fuels.

Not only would this effort offer some relief in the energy infrastructure, it would also aid efforts against climate change by removing carbon dioxide from the atmosphere.

“Our process also has an important advantage over battery or gaseous-hydrogen powered vehicle technologies as many of the hydrocarbon products from our reaction are exactly what we use in cars, trucks and planes, so there would be no need to change the current fuel distribution system,“ said Frederick MacDonnell, co-principal investigator of the project.

The corresponding paper was published in the Proceedings of the National Academy of Sciences.

“We are the first to use both light and heat to synthesize liquid hydrocarbons in a single stage reactor from carbon dioxide and water,” said Brian Dennis, co-principal investigator of the project. “Concentrated light drives the photochemical reaction, which generates high-energy intermediates and heat to drive thermochemical carbon-chain-forming reactions, thus producing hydrocarbons in a single-step process.”

The new, inexpensive catalyst could lead to the transformation of CO2 into green fuel.

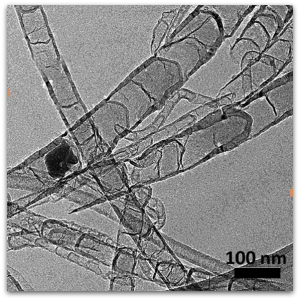

Image: Angewandte Chemie

On a global scale, carbon dioxide (CO2) is the number one contributor to dangerous greenhouse gas emissions. Increasing levels of CO2 accelerate the devastating effects of climate change, such as rising sea levels and a higher global temperature. In order to reduce these emissions, researchers are tackling projects from the implementation of a clean energy infrastructure to scrubbing CO2 from the atmosphere. The researchers from the University of South Carolina are exploring even another innovative way to reduce CO2 emissions by turning the harmful byproduct into fuel.

The team, led by ECS member Xiao-Dong Zhou, is looking for a way to harness CO2 emissions that already exist in the environment and use green technologies to inject energy and produce fuel.

Making Green Fuels

While 100 percent renewable energy may be the ultimate answer for the energy infrastructure, it is difficult for industrialized countries that heavily depend on traditional combustion technologies to make that transition so rapidly. The implementation of wind and solar technologies on the large scale also raises question to grid efficiency, reliability, and storage.

One solution to this issue is by using technologies such as solar and wind to turn harmful CO2 emissions into clean, usable fuels.

Scientists working in the field of synthetic photosynthesis have recently developed an artificial “leaf” the can produce natural gas from carbon dioxide. This marks a major step toward producing renewable fuels.

Through a combination of semiconducting nanowires and bacteria, the researchers were able to design an artificial plant that can make natural gases using only sunlight—making the likelihood of a cleaner future more tangible.

From Organic to Synthetic

The roots of this development stem for the natural process of photosynthesis. Instead of the natural byproduct of organic photosynthesis (sugar), these scientists have produced methane.

“We’re good at generating electrons from light efficiently, but chemical synthesis always limited our systems in the past,” said Peidong Yang, head researcher in the study. “One purpose of this experiment was to show we could integrate bacterial catalysts with semiconductor technology. This lets us understand and optimize a truly synthetic photosynthesis system.”

There are more than 250 million cars and trucks on U.S. roads. From these vehicles, roughly 135 billion gallons of gasoline are consumed each year in the United States. In fact, 28 percent of energy used in the country is in the transportation sector.

While many may think that the majority of this consumption would come from planes or trains, personal cars and trucks actually consume 60 percent of all energy used here. Unfortunately, most of that energy is lost to heat and other inefficiencies within the vehicles, leaving only about 10 to 16 percent of a car’s fuel being used to actually drive and overcome road resistance.

However, the researchers at Virginia Tech may have a partial solution to this problem: harvesting energy from a car’s suspension.

The development could help lead to safe, efficient artificial photosynthetic systems that replicate the natural process of photosynthesis that plants use to convert sunlight, water, and carbon dioxide into oxygen and fuel in the form of carbohydrates, or sugars.

Source: Caltech

The Electrochemical Society’s Nate Lewis is leading some pioneering research at Caltech with the vision of efficient, affordable, and effective renewable energy sources.

Dr. Lewis, an active member of ECS since 1982, has designed a novel electrically conductive film – which has the potential to result in the development of devices that can harness sunlight to change water into hydrogen fuel.

(Take a look at his plenary lecture on sustainable energy technology he gave at a past ECS meeting.)

“We’ve discovered a material which is chemically compatible with the semiconductor it’s trying to protect, impermeable to water, electrically conductive, highly transparent to incoming light, and highly catalytic for the reaction to make oxygen and fuels,” said Dr. Lewis.

He and his team have developed a process that allows the solar-driven production of fuel to be performed with record efficiency, stability, and effectiveness.

Recently, fuel cells have been the hot topic in energy discussions. In accordance with this, Toyota has introduced its first mass-market fuel cell car that will be available for purchase next month.

The company is calling the four-seat sedan Mirai, which means “future” in Japanese. The car will first go on sale in Japan on December 15th, followed by sales in the United States and Europe in the fourth quarter of 2015.

This from Reuters:

The ultimate “green car”, fuel cell vehicles (FCVs) run on electricity made by mixing hydrogen fuel and oxygen in the air – a technology first used in the Apollo moon project in the 1960s. Its only by-product is heat and water – water so pure the Apollo astronauts drank it.