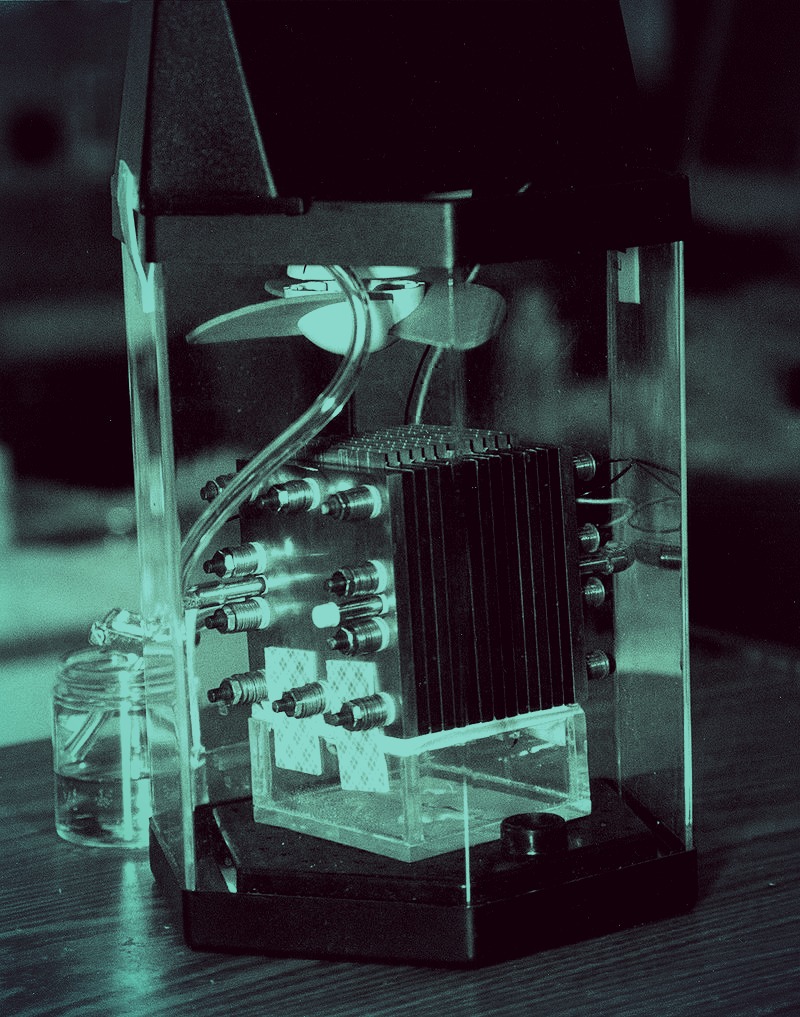

Image: CC0 Public Domain

Fuel cells have existed (at least in theory) since the early 1800s, but have spent much of their existence as laboratory curiosities. It wasn’t until the mid-1900s that fuel cells finally got their time in the spotlight with the first major application in the Gemini and Apollo space flights.

While fuel cells have moved forward in the competitive field of energy storage, there are still many barriers that researchers are attempting to overcome. Especially today, with society making a conscious effort to move toward more sustainable types of power, much emphasis has been put on solid oxide fuel cells and moving them from the lab to the market.

(MORE: Get additional information on the evolution of fuel cell technology.)

A team of researchers from Washington State University believes they may have taken a crucial step in doing just that.

Moving fuel cells forward

The team recently published a paper detailing what they believe to be a key step in SOFC improvement and eventually implementation in the marketplace. These small improvements could mean big changes.

SOFCs, unlike other types of fuel cells, do not require the use of expensive materials (i.e. platinum) to develop.

“Solid oxide fuel cells are very fuel flexible in contrast to other kinds of fuel cells, like alkaline fuel cells,” Subhash Singhal, Battelle Fellow Emeritus at Pacific Northwest National Laboratory and esteemed fuel cell expert, told ECS in a previous interview. “Solid oxide fuel cells can use a variety of fuel: natural gas, coal gas, and even liquid fuels like diesel and gasoline.”

Understanding SOFCs

However, the carbon-based materials relate to one of the barriers associated with SOFCs. When gasoline is used, it can poison and stop desired reactions. The research from the team at Washington State University helps us understand why this phenomena occurs, specifically where the anode connects with the electrolyte and fuel.

This from Washington State University:

The researchers determined that the presence of an electric field at this boundary can prevent failures and improve the system’s performance. To properly capture the complexity of this interface, they used the Center for Nanoscale Materials supercomputer at the Argonne National Laboratory to perform computations. The researchers studied similar issues in solid oxide electrolysis cells (SOECs), which are like fuel cells that run in reverse to convert carbon dioxide and water to transportation fuel precursors.

This insight may allow researchers to develop more efficient, sustainable SOFCs.

PS: Visit the ECS Digital Library to learn more about SOFCs.