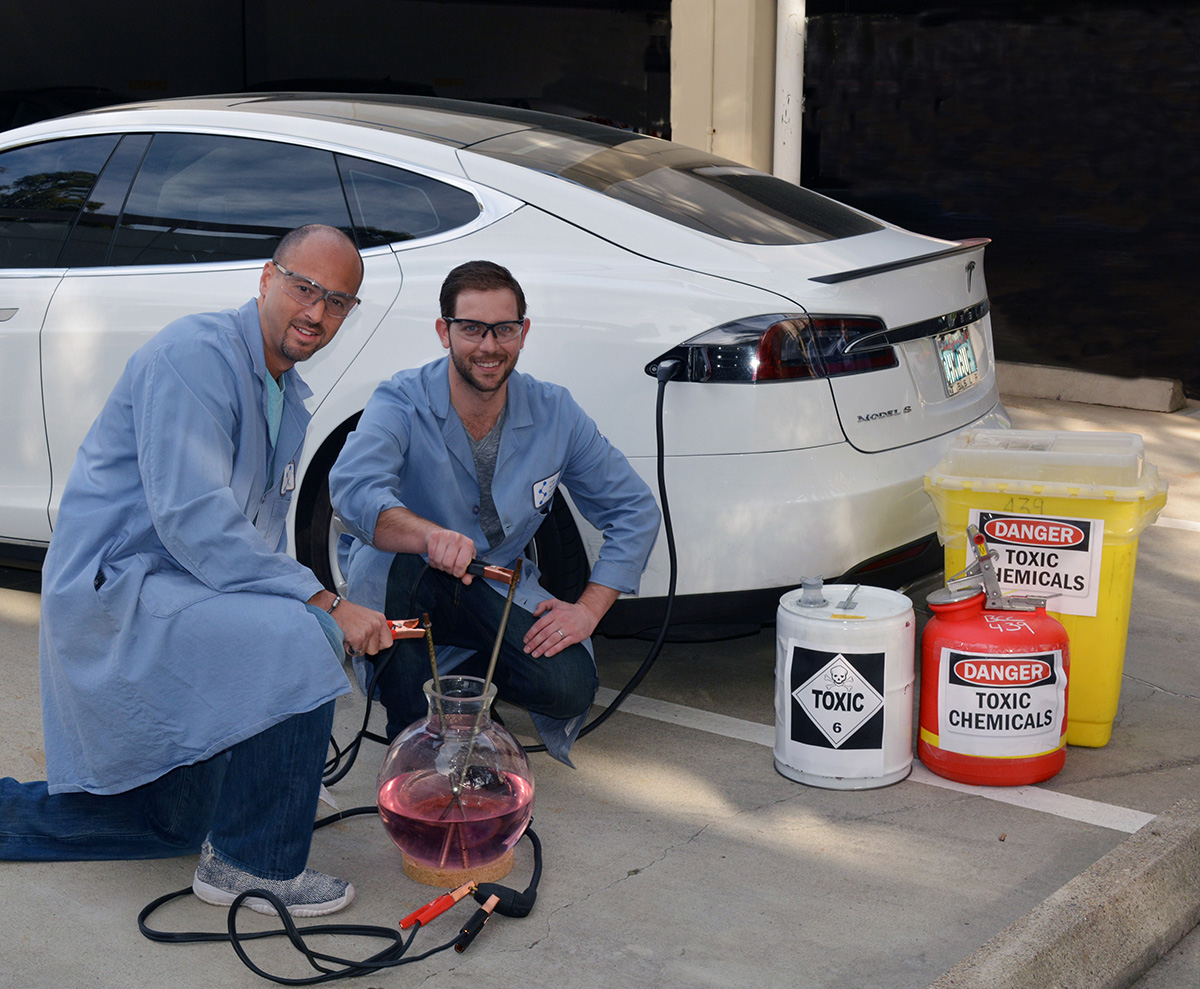

Researchers Phil Baran (left) and Evan Horn pose in front on an electric car, showcasing how the principals of sustainable transportation pertain to sustainable chemistry in the new allylic oxidation reaction.

Image: The Scripps Research Institute

Researchers from The Scripps Research Institute (TSRI) have developed a new technique that has the potential to boost a traditional chemical reaction, opening doors for new developments in pharmaceuticals and other industries.

The researchers developed an easier, cheaper, and greener way to preform allylic oxidation – a process that typically employs toxic or expensive reagents and has previously been difficult, if not impossible, to implement on a large scale. By using the power of old-fashioned electrochemistry, the TSRI researchers discovered a way to make the process scalable through the use of safe chemicals.

(READ: “Scalable and sustainable electrochemical allylic C-H oxidation“)

“Turns out one of the best reagents you can buy is sitting in your wall socket,” said principal investigator Phil Baran. “The scope of the reaction is just phenomenal. It’s super easy to do, and the overall improvement in environmental sustainability is dramatic.”

This from TSRI:

The electrodes used to transmit current through the reaction vessel are made of vitreous carbon and cost just a few dollars each. The oxygen source is not pure O2 gas—which tends to create a fire/explosion hazard at industrial scales—but a widely available liquid oxidant, tert-butyl hydroperoxide. The base and solvent are pyridine and acetone, both cheap and ubiquitous in chemistry labs. The electrochemical mediator, which assists in removing hydrogen atoms from the original molecules to make way for oxygens, is derived in one step from a non-toxic, cheap and widely available flame retardant. The electric current is regulated by a potentiostat, which in turn can be controlled by a laptop; the current source is a simple battery.

The researchers hope that this development opens the eyes of industry to the power of electrochemistry and that 10 years from now, medicinal and process chemists will have potentiostats next to their stirring plates.