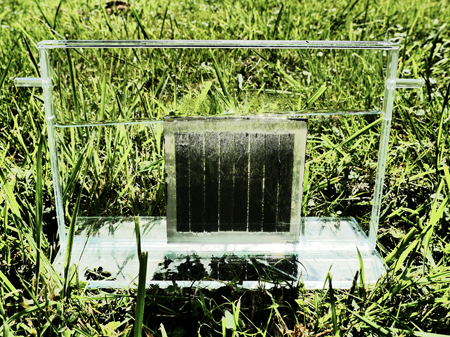

Image: Forschungszentrum Juelich

Artificial photosynthesis has carved out a promising corner in renewable energy research in recent history. This novel process is solar-driven, harvesting renewable energy and storing in in chemical bonds. Breakthroughs in artificial photosynthesis could lead to the development of solar fuels that could potentially shift the energy infrastructure.

However, while many technological barriers have been surpassed in the advancement of artificial photosynthesis, there are still hurdles to overcome. However, a research team from Forschungszentrum Juelich believes they may have just taken a significant step forward in the advancement of this field.

In a recently published paper, the team of scientists state that they have developed the first complete and compact design for an artificial photosynthesis facility.

The artificial photosynthesis process was first investigated in the 1970s. In fact, ECS Fellow Allen J. Bard can be seen here discussing the process in 1983. But only recently has artificial photosynthesis began to garner larger amounts of attention from the scientific community as a whole.

The recently released paper from Forschungszentrum Juelich tackles an issue related to the process that has been largely neglected, namely the development of a realistic design that can take the technology from the lab to practical application.

“To date, photoelectrochemical water splitting has only ever been tested on a laboratory scale,” explains Burga Turan, co-author of the paper. “The individual components and materials have been improved, but nobody has actually tried to achieve a real application.”

This from Forschungszentrum Juelich:

With a surface area of 64 cm2, their component still appears relatively small. The trick is in its flexible design. By continuously repeating the basic unit, it will in future even be possible to fabricate systems that are several square meters in size. The basic unit itself consists of several solar cells connected to each other by a special laser technique.

Currently, the solar-to-hydrogen efficiency only peaks at 3.9 percent. However, the team is hopeful that they can see numbers around 10 percent in the near future.

“This is one of the big advantages of the new design, which enables the two main components to be optimized separately: the photovoltaic part that produces electricity from solar energy and the electrochemical part that uses this electricity for water splitting,” Jan-Philipp Becker says. “For the first time, we are working towards a market launch. We have created the basis to make this reality.”