Researchers believe that as work continues in relation to this study, battery technology will accelerate forward.

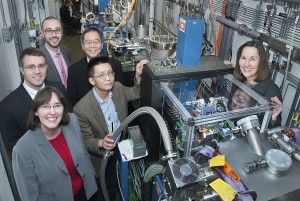

Image: Stony Brook University

A collaborative group of six researchers from Stony Brook University and Brookhaven National Laboratory are using pioneering x-ray techniques to build a better and more efficient battery.

The researchers—four of whom are active ECS members, including Esther Takeuchi, Kenneth Takeuchi, Amy Marschilok, and Kevin Kirshenbaum—have recently published their internal mapping of atomic transformations of the highly conductive silver matrix formation within lithium-based batteries in the journal Science.

(PS: You can find more of these scientists’ cutting-edge research by attending the 228th ECS Meeting in Phoenix, where they will be giving presentations. Also, Esther Takeuchi will be giving a talk at this years Electrochemical Energy Summit.)

This from Stony Brook University:

In a promising lithium-based battery, the formation of a silver matrix transforms a material otherwise plagued by low conductivity. To optimize these multi-metallic batteries—and enhance the flow of electricity—scientists need a way to see where, when, and how these silver, nanoscale “bridges” emerge. In the research paper, the Stony Brook and Brookhaven Lab team successfully mapped this changing atomic architecture and revealed its link to the battery’s rate of discharge. The study shows that a slow discharge rate early in the battery’s life creates a more uniform and expansive conductive network, suggesting new design approaches and optimization techniques.

“Armed with this insight into battery cathode discharge processes, we can target new materials designed to address critical battery issues associated with power and efficiency,” said study coauthor Esther Takeuchi, a SUNY Distinguished Professor at Stony Brook University and Chief Scientist at Brookhaven Lab.

The result of the team’s experimentation with batteries and x-ray beams has yielded proven high stability, high voltage, and spontaneous matrix formation. These results are very promising for application in implantable medical devices that require a battery with these qualities.

“The experimental work—in particular the in-situ x-ray diffraction in batteries totally encased in stainless steel—should prove useful for industry as it can penetrate prototype and production-level batteries to track their structural evolution during operation,” Takeuchi said.