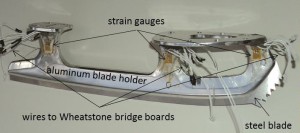

This hybrid skate has strain gauges and wires leading from gauges to Wheatstone bridge boards.

Credit: Institute of Physics Publishing

Although there may not be nearly as much physical contact as football or hockey, ice skating has been known to yield very serious injuries to its participants. During jumps, skaters can exert forces of more than six times their body weight. With training sessions consisting of 50 to 100 jumps each, it is easy to see how skating can take a toll on the body.

Now, researchers from Brigham Young University and Ithaca College are using sensor technology in existing blades to help discover how to prevent injury, as well as inform the design of a new and improved skating boot.

This from the Institute of Physics:

The strain gauges are attached directly to the stanchions where the blade connects to the boot, and when the stanchions deform due to the force induced by the ice skater, it causes the strain gauges to deform as well. Once deformed, the electrical resistance of the strain gauge changes—this change is measured by a device called a Wheatstone bridge, and a central control system is used to calculate the overall force that was imparted. The entire measuring device, including a battery, weighs 142 g and fits under the boot space of the blade so that none of the components makes contact with the ice.

Due to injuries soaring over the past few decades, skaters have been pushing for better equipment – and now through sensor technology, they will be able to have the safest, most efficient skating boot.

Take a look at the entire study here.

Sensor science and technology is growing rapidly in response to an ever-increasing demand for faster, cheaper, smaller, and more sensitive means to monitor the chemical, biological, and physical world around us. Make sure you stay up-to-date with the latest research in this exciting field through our Digital Library.