An article by C. Liu and R.G. Kelly in the latest issue of Interface.

An article by C. Liu and R.G. Kelly in the latest issue of Interface.

Localized corrosion is characterized by intense dissolution at discrete sites on the surface of a metal or alloy, while the remainder of the surface corrodes at a much lower rate. The ratio of the two rates is on the order of 10. Typical forms of localized corrosion include crevice corrosion, pitting, stress corrosion cracking, and intergranular corrosion. Localized corrosion represents the primary corrosion failure mode for passive/corrosion resistant materials.

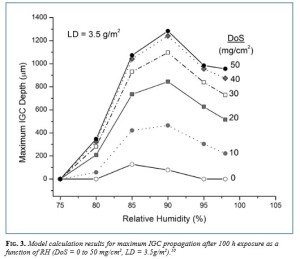

There has been extensive experimental characterization of the dependence of the susceptibility to corrosion on alloy and solution composition, temperature, and other variables. Computational modeling can play an important role in improving the understanding of localized corrosion processes, in particular when it is coupled with experimental research that accurately quantifies the important characteristics that control corrosion rate and resultant morphology. There are many modeling methods that can be applied, with the choice of method driven by the goal of the modeling exercise.

Empirical models can be used to predict performance within the parameter space for which they are created. Such models can provide insight into what kinds of processes might be dominating the corrosion process, but further dissection of controlling factors is more difficult.